Stamping Equipment

SEYI

Straight Side Crank Servo Press

C Frame Direct-Drive Servo Press

Solid Frame Crank Servo Press

“Servo application solutions, automated peripheral integration solutions, and smart stamping management systems” are the three main pillars of SEYI’s development strategy.

Dallas Industries

Underloop Space Saver

Conventional Line

Servo Tandem Line

Servo Driven Press Feed Systems

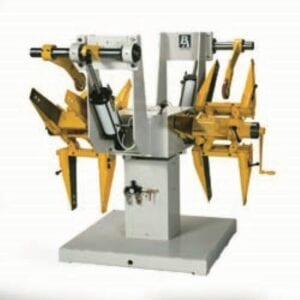

PA Industries

Shaker

Wire servo feed

Straightener

Double End Reel

Electronic Rewind

Servo Feed

Coil Feeding Lines

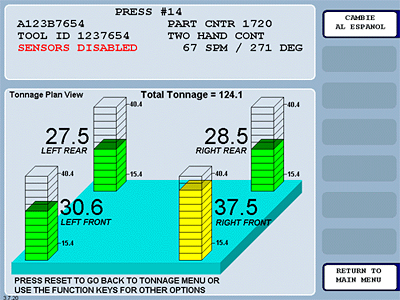

Wintriss

Servo Press-specific

ShopFloorConnect Software

DiProPAC Die Protection Module

SmartPAC PRO – AutoSetPAC Tonnage Monitor

Wintriss is the leading manufacturer of press automation, die protection, and safety controls for the metal stamping industry, and data collection software for all discrete manufacturing

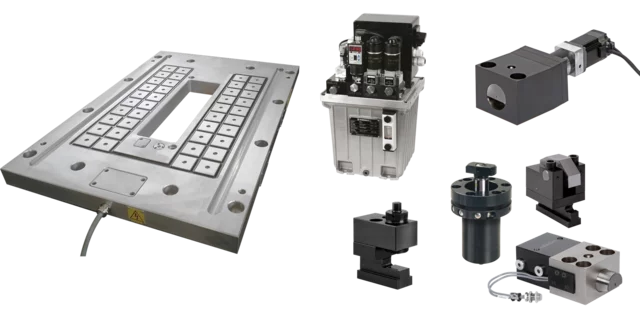

ROEMHELD

Die Changing Carts

Die Clamping Technology

Rack Systems for Die Storage

ROEMHELD North America specializes in high-performance Quick Die Change (QDC) and die handling solutions for metal stamping presses. Our advanced technologies help manufacturers streamline operations, reduce downtime, and improve workplace safety.

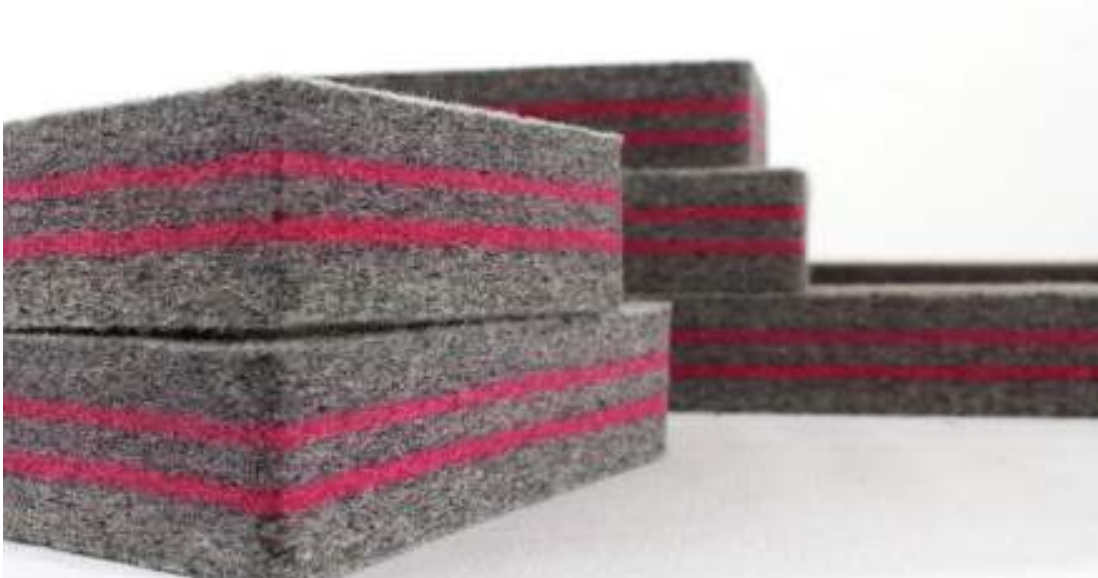

UNISORB

Fixators®

Isolation Pads

TRI-WEDGE® Machinery Mount

Your machines aren’t just equipment – they’re the backbone of your business. That’s why, for over 90 years, we’ve been relentless in our commitment to their success. We’re proud to have the only Engineering Department devoted exclusively to the design of complete machine installation systems.

At UNISORB®, we advocate for your machinery. Simply put, when your machines are happy, your business is too!